Hull

Hull integrity including windows, hatches plus antifoul, gel coat, etc.

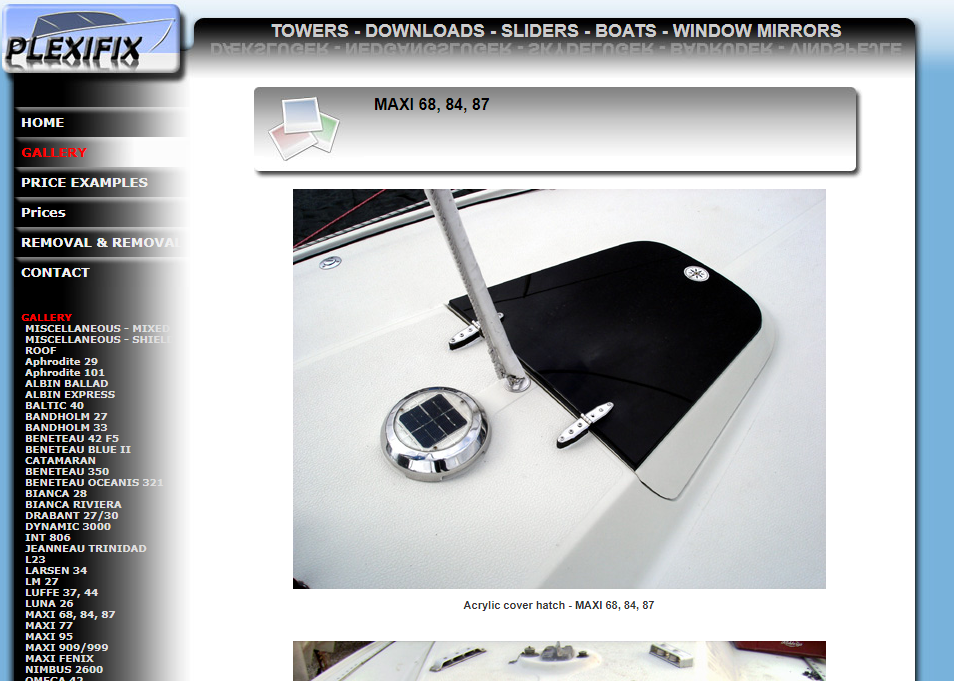

Spotted on the internet by Jim Turner is this supplier of replacement hatches and windows for certain Maxis which may be of interest. Models covered are Maxi 68, 84, 87, 77, 95, 909/999 and Maxi Fenix.

Contact details for Plexifix:

Peter Stonestreet suggested that I write up my experience of removing the keel from my 1997 Maxi 34 a year or two ago as, after the tragedy of Cheeky Raffiki, this is a topical subject. The story starts with us purchasing Ariam from Roger Moon at SD Marine in 2012. She had been chartered for most of her life and we paid an appropriate price, although being a Maxi she was fundamentally sound. After a season I noticed that the bilges were never completely dry and began looking for what must be a small, but persistent leak. On a reach to starboard, the discovery of a thin, pulsing trickle of seawater appearing from a crack in a section of fibreglass fillet at the aft end of the keel, indicated the potential source.

Deep gloom descended as my first reaction was that Ariam must have been grounded hard at some stage in her life, but Neil Desty (of Destys at Hamble Point) kindly came up to Kemps Quay to inspect the hull internally. His view was that this had not the case and the structure was in perfect condition. He was reluctant to remove the keel as “you really, really don’t want to take the keel off a Maxi” but we agreed that the only way to pin down the leak was to drop the keel. Thus Ariam was de-rigged and lifted out at Hamble Point. With all 8 keel bolt nuts undone, you might have expected the keel to come away with little resistance, but not so. After hours in the slings and much heaving and hammering from above, Desty’s troops suggested it would be better for the owner not to watch the next stage of the process. This involved cutting scallops of material out of the fibreglass, front and rear and either side of the keel, and inserting crowbars to lever the keel out of its socket. With an almighty ‘bang’ the keel eventually disconnected and sat upright in the dunnage prepared for it.

A thin, black line along the sealant indicated where water was entering through a crack at the forward end of the keel, seeping along its length and emerging through a keel bolt hole at the rear, then out through the fillet. I took the opportunity to have some corrosion pits in the keel filled, after slurry blasting the cast iron. Destys then re-coppercoated it, cleaned out the keel slot and refitted the keel with new sealant. Ariam has been bone dry ever since.

The point I took home from this was that the keel attachments in the Maxi 1000/ Maxi 34 hull are immensely well engineered. First of all the keel fits into a 2″ deep slot in the hull, ensuring there is plenty of solid fibreglass structure around it. Secondly the bending moment the keel imposes on the hull, as the boat heels, is reacted over a wide area due to the flat, flared-out top section of the keel. This makes the keel more expensive to cast, but has the added benefit of allowing the 8 keel bolts to be staggered athwartships, further spreading the load. I am very happy to see how well the boat is constructed and have no worries about the keel detaching at sea.

Having looked at new boats at the shows and disliked their light build and IKEA style interiors we decided to renovate our 14 year old Maxi 1100’s faded and much polished (and therefore eroded) dark blue gelcoat with new gelcoat in cream. Having first considered repainting or vinyl covering her top sides we decided to leave her in the most capable hands of Chris Murch of Northney Yacht Services and treat her to a totally new look!

I have had lots of inquiries regarding cost but it’s difficult to quantify. There is the haul out, mast and rigging removal, polythene watertight tent, removal of all hardware and vinyl stripes etc. I had all anti foul removed and re epoxied below waterline so that the new gelcoat could be faired in. The deck had to be cleaned and polished afterwards along with all fittings. There was approximately 100kg of gelcoat applied which after all the sanding in between coats became about 50kg but that was of course after most of the blue was removed. Then three coats of anti-foul on top of several coats of epoxy. All in we are talking about 9-10k sterling for an 1100. We are extremely pleased with the results- she is like a brand new yacht! I can most thoroughly recommend Chris and his firm for an excellent job.

David Hodges

The following failure has been reported by Maxi 1100 owner Peter Bruce.

Maxi 1100 owners might like to know that a crack has been found in the athwardships plate in the stem fabrication where it holds the forestay. The stem fabrication is not symmetrical and a stress point occurs at the weld where the athwartships plate intersects with the inboard fore and aft plate. Peter Bruce, who owns Owl, hull number 19 says the crack was well developed, and it might have led to the loss of the mast. It is just possible to view the weld in question with the forestay in position.

Following recent yachting press coverage of this issue, all Maxi Owners are encouraged to have their seacocks checked.

Maxi Owners Association member Phil Ball reported the following to us via the East Coast members contact Rod Minkey