Sails

Sails, masts and rigging, plus associated deck gear

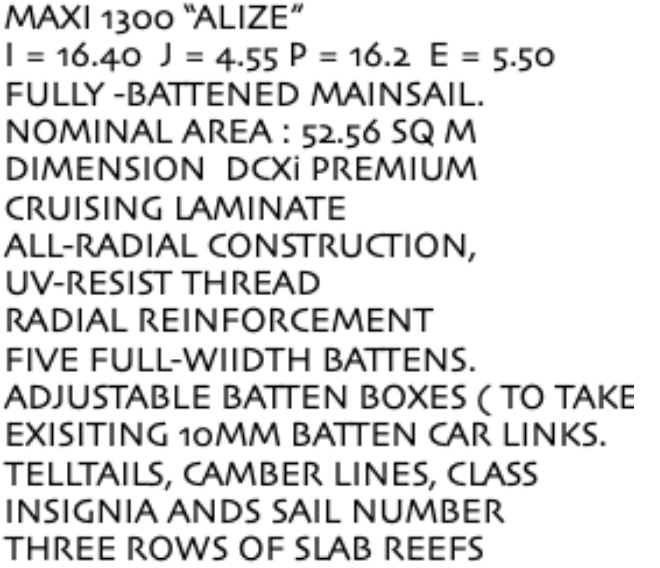

Maxi 1300 fully battened mainsail. Radial construction. Top quality Dimension DCXI laminate. Sail was made new in 2017 but the rig was changed in 2019 to in-mast furling. So it had two seasons of light use and is first class. Have priced low because it would be a shame and a waste for it not to find a new home. Full inspection possible (KT23 – Surrey or elsewhere by arrangement). Contact Mike 07917 798940

Spec for sail

The following failure has been reported by Maxi 1100 owner Peter Bruce.

Maxi 1100 owners might like to know that a crack has been found in the athwardships plate in the stem fabrication where it holds the forestay. The stem fabrication is not symmetrical and a stress point occurs at the weld where the athwartships plate intersects with the inboard fore and aft plate. Peter Bruce, who owns Owl, hull number 19 says the crack was well developed, and it might have led to the loss of the mast. It is just possible to view the weld in question with the forestay in position.

UPDATE – Darryl has found the answer to the question below.

Download pdf file of the rig setup from Selden

Maxi Owners Association member Darrel Walters has provided the following phtographs and question. If you can help him please respond through our Forum.

Choosing the ideal sails for the ideal cruiser/racer

HOW JOHN CHOSE HIS NEW SAILS FOR MAGEWIND, HIS MAXI 1050

With their combination of comfort, build quality, seaworthiness and performance, the Maxi range seem to me to offer a perfect compromise between the needs of a cruising family and my desire to get the very best performance from a boat, whether racing or passage-making.

The original standard sails were made by Elvstrom, are cross cut and made of Dacron. A performance range were also available at an additional cost and are made from a Dacron and film laminate. Later Maxi’s are supplied with North Sails.

The original sails are a 105% Genoa and a 4 batten fully battened main sail. The Genoa has vertical battens to help support the leach. An optional spinnaker or cruising-shute is also available.

Apart from upgrading these sails with tri-radial cut sails made from laminates there is the option of adding a Code Zero, Flat Asymetric Spinnaker, a large roached 105-110%, 140% or 150% Genoa.

Some of the more recent boats, hull/sail number 43 onwards, have aft sheeting tracks or the facility for these built into the deck to allow for a 140% or a 150% Genoa. Boats prior to this do not have the deck-strengthening plates and retrofitting is much more difficult due to the need of removing interior woodwork and strengthening the deck from inside the saloon / heads. The initial boats fitted with the aft tracks had the tracks positioned for a 150% Genoa, later boats had the track moved forwards 18″ (450mm) for a 140% Genoa. Currently it seems that the tracks will only sheet the Genoa they were intended for.

The 140% and 150% Genoas would probable only be needed for racing or when large crew ballast is available. The 140% and 150% Genoas will increase your racing rating to somewhere in the region of 1018, this may well mean that the boat is un-competitive in stronger winds when using the 105% Genoa.