*Maxi Yachts Update*

Maxi Yachts has been acquired by Polish boat builder, Delphia Yachts.

These details have been published on the Delphia Yachts website:-

Maxi Yachts has been always a synonymous with well-constructed vessels whose build quality has earned them great respect throughout the sailing world.

Most recently, the Maxi Yachts boatyard constructed 34-42 foot yachts, designed by world champion and Olympics medalist, Pelle Petterson. Since its establishment, the boatyard has released over 16 thousand vessels.

The core values of the Maxi brand are design, comfort and safety.

To own a Maxi yacht demonstrates one’s passion for the life at sea. The typical Maxi owner is a purist sailor seeking the perfect balance between the performance of a boat and the comfort it provides. The Maxi product range combines safety with build quality finished with an eye for the smallest detail. Experience in building yachts shines through in each craft’s functionality, ease of handling and uncompromising comfort for the crew, coupled with contemporary eye-catching Scandinavian styling.

Despite the unmistakable attention to detail and design, these vessels feature excellent nautical capabilities that have earned them loyal enthusiasts worldwide.

It is the firm opinion of Delphia Yachts Kot sp. j., that Maxi yachts deserves to continue to produce fine craft to allow future generations of sailors to forge their character onboard such excellent vessels. Therefore, we regard the acquisition of Maxi Yachts as part of Delphia’s strategic development, going the extra mile to meet clients’ expectations, always seeking new solutions and continuously increasing our product range. The range currently features 10 sailboats, 3 house boats, and some 20 classic models of motorboats and speedboats. Maxi models complement the current Delphia lineup and therefore it is our intention to breathe new life into such beautiful and inspired designs.

Delphia Yachts is a constantly growing company, constantly seeking new challenges. We feel that acquiring Maxi Yachts presents a great challenge – one that takes preparation, investment and time to achieve the desired results. By acquiring Maxi, we are able to expand our dealership network and establish our leading position in a market inspired by such legends and icons of sailing style as Pelle Petterson.

All Maxi yachts will be produced at Delphia Yachts shipyard. At first Delphia plans to restart the production of existing models (Maxi 1300, Maxi 1060 and SM 40) and hopes for the future increase of Maxi Yachts fleet. The positioning of Maxi brand remains unchanged.

It is generally appreciated that yacht building is a highly complex process requiring specialized technical knowledge and skill.

At Delphia Yachts, we combine these attributes with experience, passion and advanced technology allowing us to create a superlative product which will be evident in the first models of Maxi Yachts to leave our production line.

Full details about Delphia Yachts, including the aquisition of Maxi Yachts can be found at http://en.delphiayachts.net/home-page

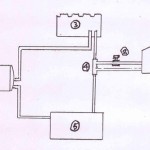

Judging by the articles on the MoA website and the Web, it appears generally acknowledged that the Ardic heater which as installed by Nimbus, is less than effective at heating the cabins. We had the heater unit serviced last winter by the local agent and whilst resolved the sooty deposits on the stern, the heating was no better. It appears that in pre heating the engine, heat the fresh water and the cabin is beyond the capabilities of the system unless also running the engine. The basic problem is that the system initially heats the cast iron mass of the engine which I believe takes 3kW, therefore the temperature of the air to the cabin is cool to say the least. The pipework diagram in the manual suggests that this should not be the case, but on a cold day working on the engine with the heating on, the engine was starting heating up but the cabin was not.

Maxi 1100 “Second Rebellion”

Navigation electronics, a cost effective option to having GPS plotters at both the navigation table and at the helm

The 2001 yacht was purchased in August 2008 and it came with a Raymarine RC530 colour plotter at the chart table, a Raytheon RL70 at the helm and a Seatalk interface which integrated the radar. Unfortunately the helm plotter was not readable in daylight, so something had to be done.

- As the yacht had the seatalk interface and all other instruments/radar were Raymarine, we only considered that manufacturer’s equipment.

- We established that the radar scanner would be compatible with the current Raymarine E80 range of plotters and we could also have AIS, however the E80 equipment would not interface with the RC530 existing plotter.

- The obvious but expensive option was to replace both plotters. However, Raymarine in common with other manufacturers, do not market a repeater for the plotter, you just buy 2 of them at around £2k each.

- However with the help of a friendly engineer in the local agent, it was revealed that you did not need a second plotter. An E80 (or E120) at the helm with a VGA cable to an inexpensive LCD computer screen (they are all 12volt), can be used to feed the screen at the chart table linked with a Raymarine keyboard, which they market for the huge screens on power boats. This option is actually better than 2 E80’s, as the PC screen can be larger and as in ours in “letter format”, which is ideal for split screen plotter/data/radar viewing. I believe that the latest “C” series plotters may also have the repeater facility.

- As it happened we had a spare PC screen so it cost us nothing, the screen swivel mount cost about £20 and the quite neat keyboard was £300 plus VAT, quite a saving on £2k and a better option all round.

- All E80 functions can be duplicated below using the keyboard and the PC screen can be swivelled to the saloon to entertain the grandchildren with DVD’s (from a player) with surround sound through the boat audio system.

- The only downside is that manipulating the data from the chart table, also changes the plotter screen at the helm.

- Both old plotters found a ready market on E-Bay, to help offset the cost of the new equipment.

The system has been extensively used for 3 seasons over 5knm without problems and a recent comment from the local agent for Raymarine was “I don’t know why more people don’t go this route”. I do…they just do not know the option is available.

Jim & Eric Sey

Pics:

-

Nav. station, Mount, and Keyboard in use

-

Keyboard parked